In an age where data-driven decision making is revolutionising manufacturing, conventional connectivity solutions often fall short of meeting industry needs. Output Industries is disrupting the status quo with Busroot, a manufacturing performance platform powered by Blues.

Manufacturing thrives on actionable data, but most connectivity solutions make that surprisingly difficult to get. While promises of smart factories sound great in theory, traditional systems often leave teams drowning in data with little useful insight to show for it. Output Industries saw this disconnect and created Busroot, a platform that empowers manufacturers to optimise performance by monitoring energy efficiency, asset utilisation, and production output across entire operations. Powered by Blues’ Wireless for Opta, Busroot delivers what manufacturers actually need: clear, actionable intelligence without the technical headache.

Blues’ Wireless for Opta are proud of their role in helping Busroot succeed. Wireless for Opta ensures that output.industries remote monitoring never misses a beat. In this case study you’ll discover:

• Real-time data drives immediate profit protection: Busroot transforms data into actionable business intelligence, helping manufacturers like metal recycling companies determine exact energy costs per unit of production to make instant decisions about profitability thresholds.

• Cellular connectivity eliminates IT barriers: By leveraging Blues’ Wireless for Opta, Output Industries bypasses traditional network complications through secure cellular connections, allowing them to deploy Busroot monitoring systems in days instead of weeks without waiting for IT approvals.

• Plug-and-play implementation accelerates ROI: Output Industries enables same-day Busroot installations that deliver 20-25% productivity improvements, fundamentally changing how their clients view IoT projects from lengthy implementations to immediate value generators.

Output Industries: Redefining performance optimisation

Data and the insights AI and ML can derive from it are becoming manufacturing’s new currency. Reports show 85% of manufacturing leaders have already invested in AI or machine learning or plan to do so soon. And the market for IoT in manufacturing? It’s booming, projected to hit $278.69 billion this year and expected to grow beyond $909 billion by 2032.

However, the makers of connected devices face obstacles, and Output Industries was no exception. When it comes to connectivity, relying on WiFi means building custom networks with complex security protocols, adding another layer of complication to an already challenging process. Connected devices in manufacturing settings have to transmit data on factory floors crowded with heavy machinery inside concrete structures. When these devices disconnect, manufacturers lose out.

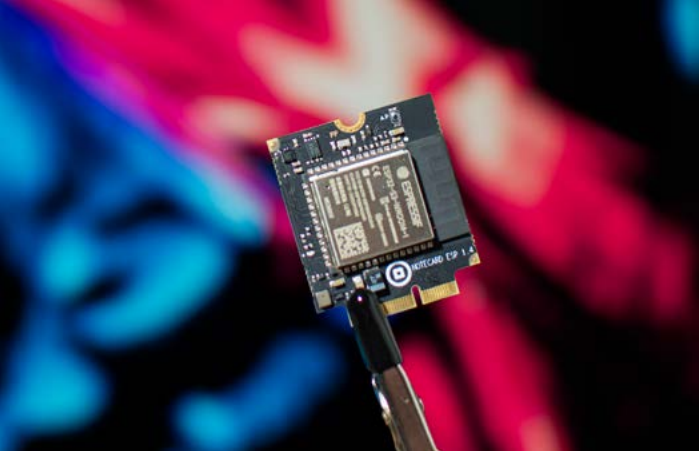

Output Industries saw an opportunity to create a connected product that sets itself apart in an industry that can make digital transformation for manufacturers cumbersome and costly. They found the key to unlocking the potential of Busroot with Wireless for Opta. This plug-and-play expansion provides a reliable foundation for Busroot’s cellular and WiFi connectivity. This ability to connect seamlessly and reliably transmit valuable operational data translates into cost savings for Output Industries’ customers.

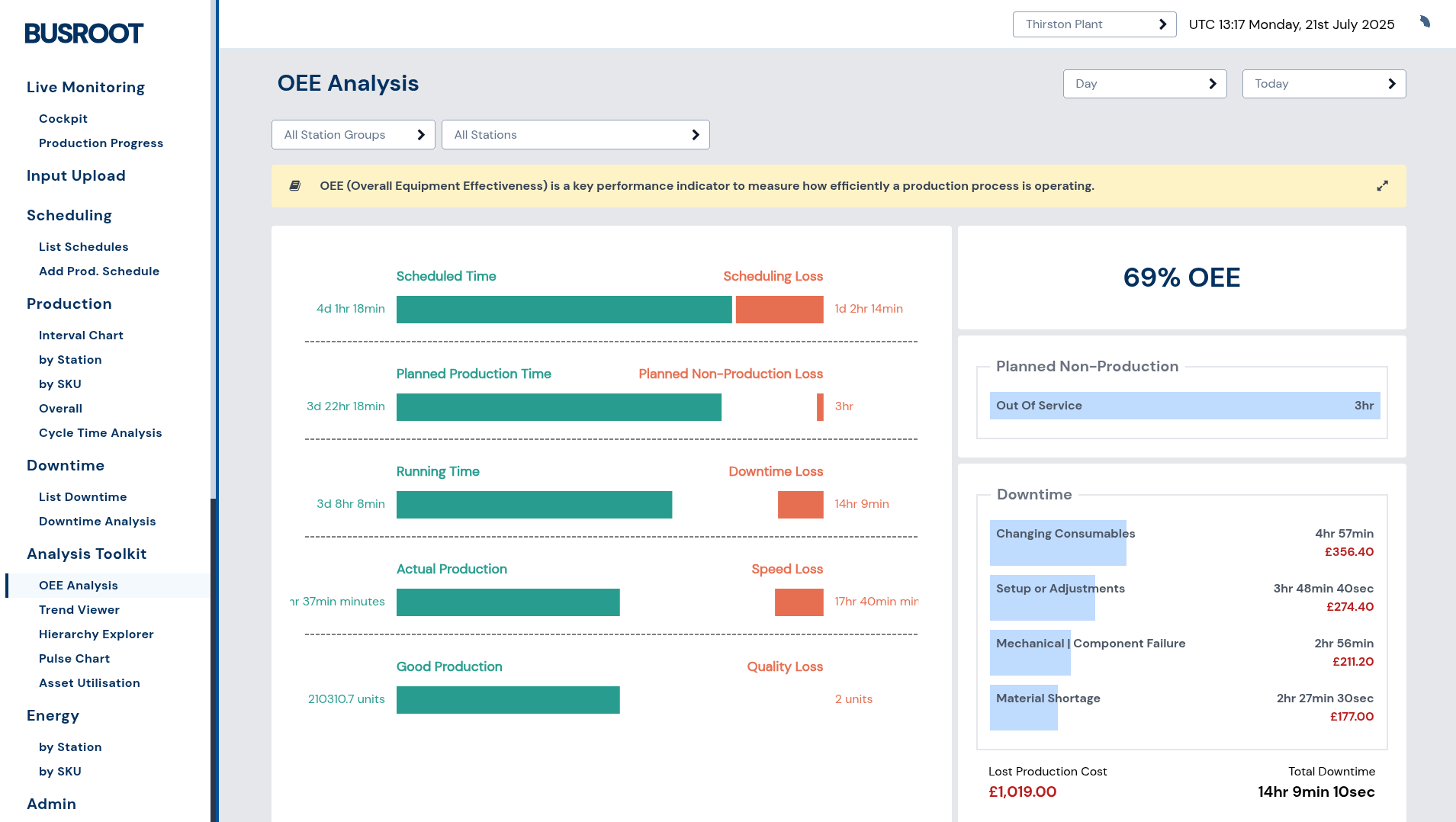

“More and more data-driven decision making is coming into the mindset of people in manufacturing,” says Tom Baker, Chief Technology Officer and Co-Founder of Output Industries. “One thing Busroot offers is that it quantifies in time and money the cost of a lot of things. We have downtime analysis, we can tell you how many minutes a station was down and for what reason. Then you can quantify that in pound, dollar or euro value.”

When Busroot puts a pound value on downtime or inefficiency, it changes the conversation from vague technical issues to clear business priorities. Manufacturers can finally see exactly where they’re losing money and make targeted improvements that deliver immediate returns.

How Blues enables seamless connectivity for Busroot

All too often, brilliant operational technology (OT) applications like Busroot get stuck behind mountains of IT paperwork and technical hurdles. Blues saw that smart manufacturing solutions were collecting dust while waiting for network approvals. That’s why they developed Wireless for Opta, to put the power back in the hands of OT teams, creating a quick, easy, and bureaucracy-free route to cloud-connected PLC systems.

For Output Industries, Wireless for Opta creates the perfect foundation for Busroot’s manufacturing intelligence platform. The secure and easy-to-use micro-PLC with IIoT capabilities supports intuitive programming and PLC standard languages. The Wireless for Opta provides plug-and-play cellular connectivity to IoT devices to create an industrial-grade solution that bypasses traditional IT barriers.

This innovative approach allows Output Industries to:

- Bypass IT roadblocks — Wireless for Opta enables Busroot to connect directly to

cellular networks, routing data through a dedicated secure VPN tunnel. Sensitive data

never enters manufacturers’ networks. This capability allows Output Industries to deploy Busroot at customer sites in days, not weeks, without waiting for IT approvals or network configurations. - Adapts to manufacturing environments — The Cell+WiFi configuration of Wireless for Opta gives Busroot reliable connectivity even in remote factory locations or metal-heavy environments where WiFi-only solutions fail.

- Connect Busroot data to any cloud without coding — Production data is routed from Busroot to its analytics platform using Notehub, our cloud orchestration layer for bi-directional data routing, saving development time and resources.

- Cut Busroot implementation from weeks to days — Busroot delivers value to manufacturers quickly thanks to pre-provisioned connectivity from Blues with end-to-end security, plug-and-play hardware, and compatibility with any cloud platform. This speed-to-implementation dramatically shortens the traditional industry sales cycle, further setting them apart.

- Protect sensitive production data — With end-to-end encryption from Wireless for Opta, Busroot secures manufacturers’ valuable production metrics without requiring additional security solutions, building trust with security-conscious clients.

- Stay ahead of factory power problems — Thanks to reliable cellular connectivity, Busroot detects issues like equipment overheating and power outages instantly, alerting operators and capturing critical production data even during disruptions, ensuring no valuable insights are lost when problems occur.

Blues provides reliable connectivity, secure data transfer, and ready-to-use hardware that lets Output Industries focus on innovation. Wireless for Opta creates a seamless path from setup to results, removing IT obstacles and giving them a major advantage in a market where speed and reliability are crucial.

How Blues and Busroot are transforming data-driven manufacturing decisions

Output Industries’ Busroot platform demonstrates how the right connectivity solution can transform manufacturing operations from reactive to proactive. By partnering with Blues, they’ve created a monitoring system that delivers real-time insights manufacturers can instantly use, turning complex industrial data into clear profit indicators. Here’s how they overcame the traditional challenges of IoT implementation to deliver measurable results for their clients.

Ensuring high uptime and reliability for critical business metrics

In energy-intensive industries, continuous access to real-time data is essential for profitability. Busroot leverages reliable connectivity to deliver these mission-critical insights without interruption.

Some competitors’ monitoring systems only report total energy consumption without context. They’re basically selling a fancy monitoring system that gives you the same data you can find on your monthly utility bill. Here’s an example from one of Output Industries’ customers: a metal recycling company needed to determine the energy output threshold for when heavy metals become too expensive to process. Busroot tracks energy usage in relation to production output. This creates a far more valuable metric: energy cost per unit of production.

“Some of these recycling processes are incredibly energy intensive,” explains Baker. “Having that input cost per ton of output is actually a make-or-break metric. Manufacturers need to know how much energy they’re putting into the process to determine if it’s a profitable endeavor.”

The system also identifies idle time, helping companies eliminate wasted energy; a benefit only possible with continuous, reliable monitoring. With Blues powering its connectivity, Busroot maintains a constant data stream even in harsh industrial environments, ensuring manufacturers always have the insights needed to make profitable decisions. When processing facilities reach the threshold where certain materials become unprofitable to recycle, having this data in real-time allows immediate operational adjustments rather than discovering losses at month-end.

End-to-End Security without the IT headaches

Unlike conventional solutions that require extensive network integration, Wireless for Opta provides robust end-to-end encryption through a dedicated VPN tunnel. This creates a secure pathway from your factory floor directly to the cloud.

“Blues has end-to-end security built into it that you don’t get with other products,” explains Baker. “We have Blues credentials to say this is end-to-end encrypted. This is a VPN tunnel that gets created from the cabinet where you put that device all the way through to the cloud. IT team, you don’t need to worry about that. Because it goes over a cellular network it doesn’t even touch their network.”

This approach not only strengthens data protection but and dramatically simplifies implementation. Manufacturers can deploy powerful IoT solutions without lengthy security reviews or complex network configurations. The cellular-first approach means operational technology remains isolated from potential IT network threats while delivering critical insights to decision-makers.

Accelerating time-to-market

Rather than making their clients wait through lengthy implementation cycles, Output Industries delivers immediate value because of Busroot’s plug-and-play setup.

“We try to be different from other incumbents in the industry who tend to work on six-month, yearlong cycles,” says Baker. “We’re working on months if not weeks: have a meeting, discuss what they’re going to be able to get in terms of value, come on site, get the device in, get them the data, and get them some answers.

“Without Blues, we’d have to visit each client facility and conduct extensive assessments around every machine they want to monitor—checking if it’s within WiFi range, configuring network access, and more.”

Wireless for Opta features an external antenna to ensure strong connection even in challenging environments, while cellular data transmission bypasses WiFi restrictions altogether. These smart features transform what could be weeks of technical setup into a same-day implementation. Output Industries’ clients can handle the installation themselves using their own teams. No expensive third-party contractors, no complex network configurations; just attach the device and start collecting data.

Plus, speedy implementation allows Busroot to demonstrate its value to manufacturers in days, not weeks The plug-and-play nature of both Busroot and Blues means manufacturers can generate insights immediately, which completely changes their perception of digital transformation projects. Showing the tangible benefits has generated high demand among customers who want to scale their use of the platform, and generated revenue for Output Industries.

“You can potentially have five to ten devices implemented and transmitting data within a day, which is unheard of,” notes Baker. “That’s what buys us a lot of goodwill with manufacturers. All of these technology solutions, from cloud computing through to the nuts and bolts of hardware; having all those things joined together seamlessly is really fantastic.”

Busroot and Blues: Shaping the future of manufacturing

The Blues-powered Busroot solution delivers measurable value to manufacturers with speed and consistency. Data from the Innovate UK Smart Manufacturing Data Hub (SMDH) project confirms that Output Industries’ clients typically see productivity gains of 20-25% without requiring additional staff, infrastructure, or external consultants.

“We work in a skeptical industry,” says Baker. “A lot of sales people knock on manufacturers’ doors, overpromising and underdelivering. We’re really delivering value early and often. That gets you the credibility that ‘these guys really follow through with what they’re saying.’”

With Blues as its connectivity foundation, Busroot delivers immediate results through simplified implementation, continuous data monitoring, and actionable insights that drive operational efficiency for manufacturers. The plug-and-play expansion for industrial PLCs adds reliable cellular and WiFi connectivity, and seamlessly routes data to any cloud without complex coding. This complete connectivity solution from Blues enables manufacturers using the Busroot platform to benefit from improved uptime, optimised energy usage, and data-driven decision making without complexity, security concerns, or IT bottlenecks.

Output Industries and Blues work together to make manufacturing data easier to access and use. Busroot helps manufacturers get the information they need to make better decisions and improve their operations.

Ready to power your IoT solutions with reliable, secure connectivity?

Book a short demo to understand how Busroot can support your digital transformation journey. Book Call